Flexible Graphite Gasket Material

Flexible graphite sheet gasket material was once thought of as a specialty gasket material for extreme temperatures and chemical services. Today, due to economies of scale, and increased competition, flexible graphite has become an affordable option for the majority of applications. The main reason is flexible graphite can replace a wide range of gasket materials, making selecting the right material for the job safe and simple. Where you once had to have many variations or gasket materials, flexible graphite makes the selection process easy.

High Temp applications to 850 F - No question, flexible graphite will seal it!.

High Temperature applications over 850 F - The answer still can be flexible graphite. This is true for 2 reasons:

1) Some grades of flexible graphite contain an oxidation inhibitor giving it the capability of sealing up to 900 F.

2) Heat is not the first thing to attack flexible graphite, it′s oxygen and heat together.

Flexible graphite can withstand up to 5,400 F as long as oxygen is not present. At 850 F and above it′s a sliding scale. In reduced oxygen atmosphere such as steam, flexible graphite will handle 1200F. If you have doubt′s about your application please contact us at support@aspseal.com

Chemical applications that once could only use Kalrez, Viton, Chemrez, PTFE, or Gylon, flexible graphite will seal it most of the time (depending on pressure). Because sulfuric acid and Nucleic acids are used to produce flexible graphite, reintroducing it to those chemicals can also break it down.

Steam Applications - Flexible graphite will seal it. When using flexible graphite on stem flanges, be aware that while the steam is sealed, due to flexible graphite′s conductivity characteristics it can appear to “sweat” (but not leak) in humid areas.

Oil and Gas we once always sealed with non-asbestos gasket materials. While non-asbestos does a good job, flexible graphite gasket material does a better job! EQMD, Air quality leakage rates control is met everyday by refineries around the world using flexible graphite. Like most materials, it is possible to replace non-asbestos with flexible graphite in the interest of standardizing on one material.

Where you don′t want to use flexible graphite is in Food, FDA, NSF, or any application where graphite contamination could be an issue. Flexible graphite will particle transfer. It′s carbon, so it will act like a lead pencil.

Plain Flexible Graphite

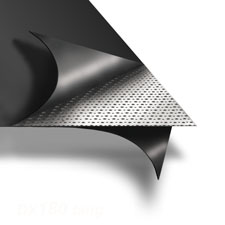

Flexible Graphite w - SS Foil Insert

Flexible Graphite w - SS Tang Insert

Flexible Graphite Gasket Material

Flexible graphite made from material typically 98% graphite. Leachable chloride typically less than 50 ppm. Sulfur content: 1200 ppm. Compressibility: 45% Recovery: 20%. Creep relaxation: 5%. Density: 62.4 lbs/ft. Tensile strength: 700 PSI. Temperature range (oxidizing atmosphere): -400” F to 750” F.

316 S.S. Foil Inserted Flexible Graphite Material

Flexible graphite sheet reinentorced with a 316 stainless steel foil (0.002” thick) made from material typically 98% graphite. Leachable chloride typically less than 50 ppm. Sulfur content: 400 ppm. Compressibility: 35%. Recovery: 18%. Creep relaxation: 12%. Density: 62.4 lbs/ft. Tensile strength: 5000 PSI. Temperature range (oxidizing atmosphere): -400° to 750° F.

316 S.S. Foil Inserted Flexible Graphite Gasket Material

Flexible graphite sheet laminate gasket material with tang 316 stainless steel insert (0.005” thick) made from material typically 98% graphite. Leachable chloride typically less than 50 ppm. Sulfur content: 400 ppm. Compressibility: 35%. Recovery: 18%. Creep relaxation: 10%. Density: 62.4 lbs/ft. Tensile strength: 5000 PSI. Temperature range (oxidizing atmosphere): -400 ° F to 750° F

Ph: 714-593-9780 Fax: 714-593-9701

E-Mail: sales@americansealandpacking.com

Call American Seal & Packing for your gasket material requirements. .